Choosing the right equipment for beer packaging can boost productivity and maintain the quality you need. Many are considering smaller lines for their flexibility. A small-scale 2000 CPH (Cans Per Hour) beer can filling line is a compact solution for breweries requiring efficiency with limited space. It includes essential machinery for filling, sealing, and packaging beer in cans.

This line accommodates small production demands without sacrificing quality. Let's examine its components, costs, and setup efficiency for breweries aiming for cost-effective operations.

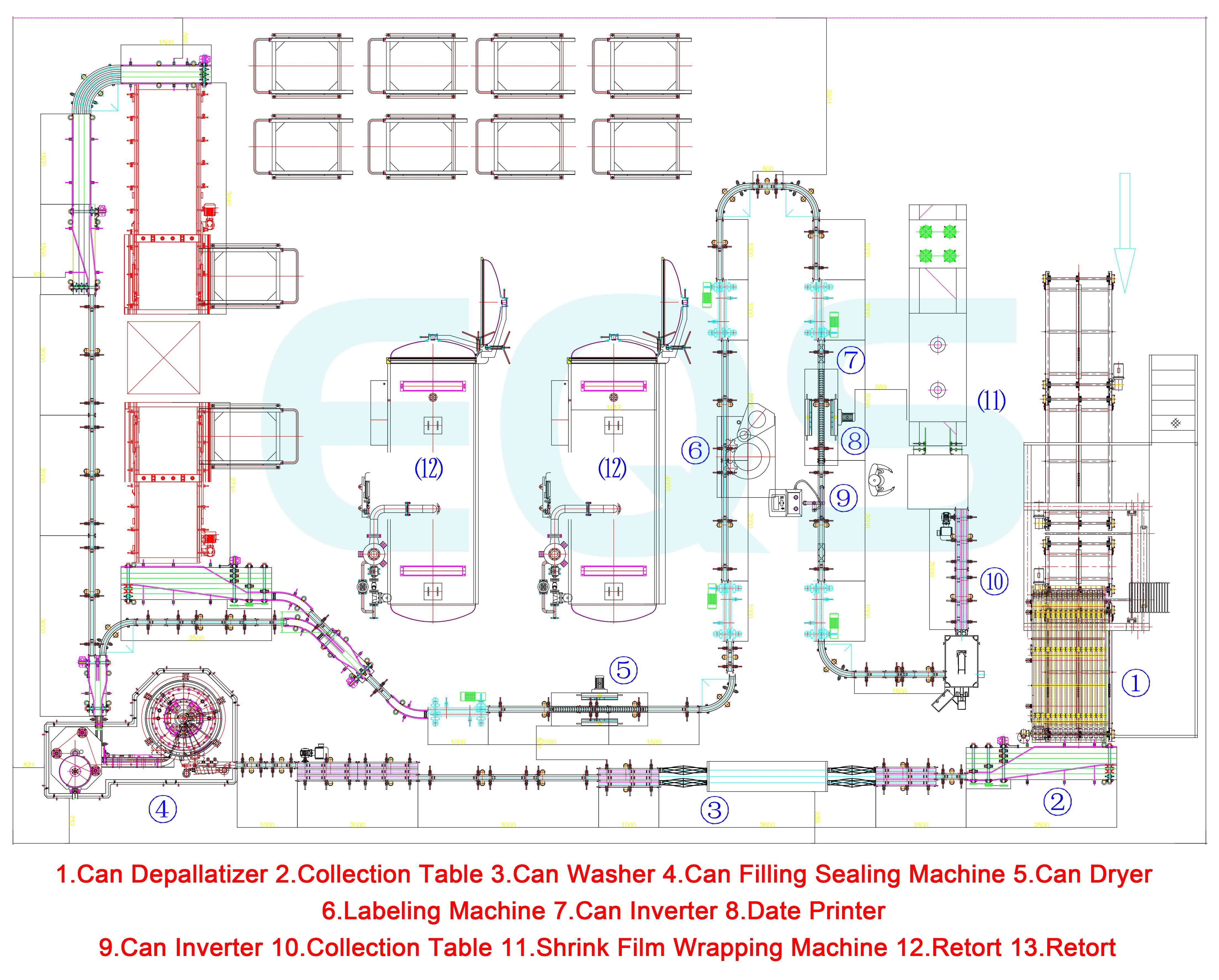

Efficient beer can filling requires specialized machinery that works together seamlessly. Getting familiar with these components can streamline brewing processes. A 2000CPH beer can filling line consists of several components: a depalletizer for moving cans, a rinser to clean cans before filling, a filling machine for dispensing beer, a seamer to seal the cans, and, finally, labeling and packaging machinery for the final product presentation.

Here's a closer look:

Understanding the investment helps align budget constraints with production goals, crucial for decision-making. The cost for a 2000CPH beer can filling line can range from $80,000 to $100,000 depending on the technology, automation level, and brand. Customized options may increase costs but offer enhanced features and durability.

Consider these factors:

Choosing the right filling line can significantly impact operational efficiency and product quality for a brewery. The primary benefits of a 2000CPH can filling line include increased production efficiency, higher precision and consistency in filling, reduced labor costs due to automation, and improved can integrity with superior sealing and handling mechanics.

A small-scale 2000CPH beer can filling line offers breweries an efficient, cost-effective way to meet production demands without compromising quality or efficiency.

Copyright © JIANGSU EQS MACHINERY CO.,LTD