Cleanliness is crucial in any beverage production line. Without efficient cleaning, product quality can suffer. Bottles must be spotless to ensure customer satisfaction and safety.

Industrial bottle washers play a pivotal role in maintaining cleanliness standards. They effectively clean bottles, removing residues and contaminants, ensuring each bottle is ready for the next step in the production process.

Keeping your bottles clean safeguards product integrity and boosts your brand's reputation. Explore how these machines make a difference.

Achieving thorough cleanliness relies on sophisticated technology. Understanding their operation highlights their importance in production.

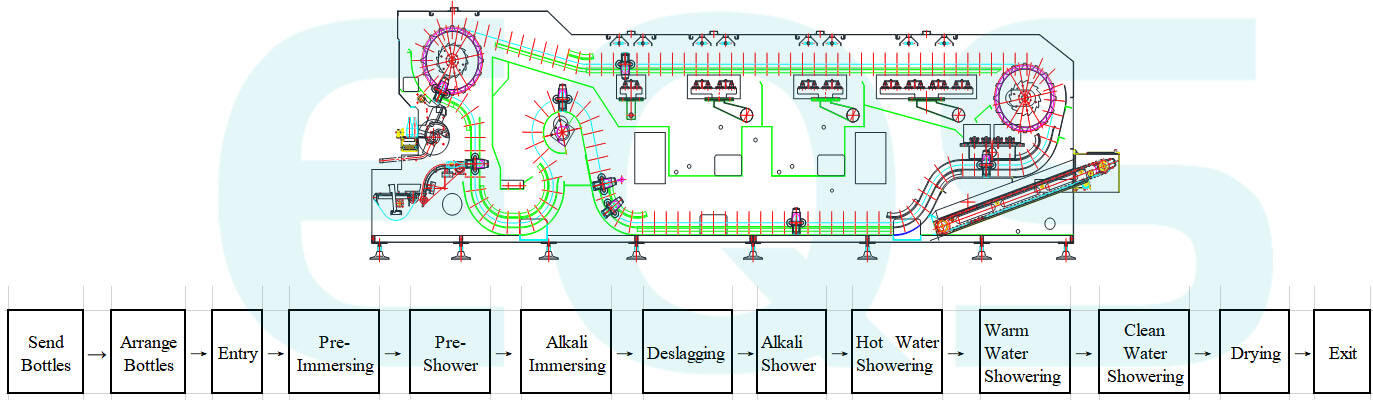

Industrial bottle washers operate using a series of jets and soaking stages that scrub and rinse bottles thoroughly. The process ensures that both internal and external surfaces of the bottle are cleaned, removing contaminants and reducing microbial presence.

This method ensures that even the toughest residues are eliminated, readying bottles for refill.

The right equipment can maximize efficiency and cleanliness, crucial for any production line success.

Industrial bottle washers provide several benefits, including a substantial reduction in labor costs, consistent cleaning results, improved sanitation levels, and compliance with health regulations, ensuring safety and customer satisfaction.

Exploring potential obstacles can inform smarter buying decisions and smoother integration.

Implementing industrial bottle washers has challenges, including high initial investment costs, space requirements, and maintenance needs. However, the long-term benefits often outweigh these initial challenges through enhanced efficiency and reliability.

Understanding these challenges helps in strategizing an effective integration for better outcomes.

Industrial bottle washers are an essential component for ensuring maximum cleanliness and operational efficiency in beverage production lines.

Copyright © JIANGSU EQS MACHINERY CO.,LTD