|

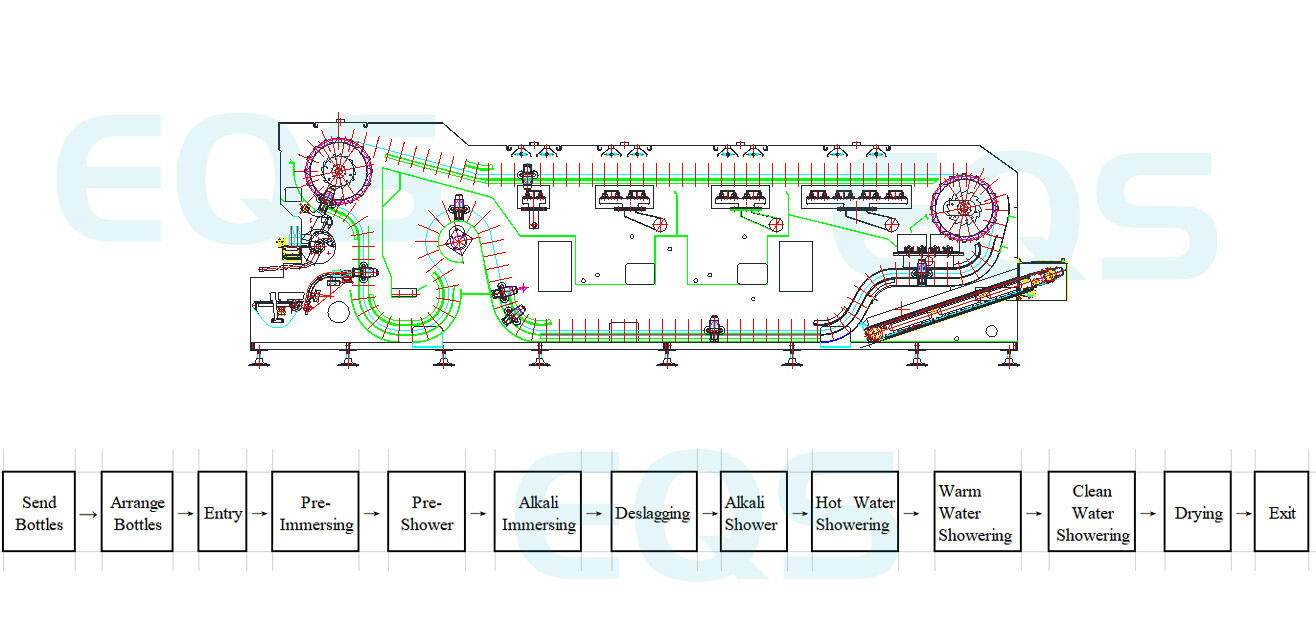

Structural Form |

Soak and Spray type |

|

Rated Production Capacity |

3000BPH |

|

Chain Pitch |

155 mm |

|

Variable-frequency and Speed-regulation Range |

1000-3000 Bottles/Hour |

|

Bottle-box Spacing |

120 mm |

|

Suitable Bottle Diameter |

Φ69-92mm |

|

Suitable Bottle Height |

260~300 mm, customized |

|

Bottle-box Quantity per Row |

7 |

|

Rows Quantity for Bottle-box (Total Rows) |

168 |

|

Total Number of Bottle Boxes |

1176 |

|

Bottle-box Total Time of Passing |

19.44min |

|

Soaking Time |

7.35min |

According to the single-end principle, the bottle push-in and push-out are completed on the same side, and the whole machine can only be operated by one person, which saves manpower, is convenient to maintain, and has the highest biosafety. The pre-cleaning device heats the bottle and removes coarse dirt. Then, each bottle stands on a horizontal loop track and passes through the lye soaking tank, the hot water tank and the warm water tank in order to completely wash away the dirt. Before the bottle leaves the machine again, it will be cooled by a small amount of fresh water in the post-treatment area, and the final residual dirt and lye will be removed

With over 20 years of industry experience, we have established ourselves as a leading provider of beverage production line solutions worldwide. Our state-of-the-art manufacturing facility spans over 50,000 square meters and is equipped with advanced machinery and technology.

We pride ourselves on our commitment to quality, innovation, and customer satisfaction. Our team of experienced engineers and technicians work closely with clients to understand their specific needs and deliver customized solutions that exceed expectations.

Q1: Are you a trading company or a manufacturer?

A1: We are a manufacturer, we supply the factory price with good quality,our Engineer Team with over 20 year's experience,welcome to visit!

Q2.How can I know your machine has good quality?

A2:We will send the video of testing the machine working condition for you before delivery,so you can send us your bottle samples for a trial.

Q3:What's your guarantee or the warranty of the quality if we buy your machines?

A3: We offer you high quality machines with 15 months guarantee and supply life-long technical support.

Q4: When can I get my machine after I paid?

A4: The delivery time is based on the exact machine you confirmed.

Q5: How can I install my machine when it arrives?

A5: We will send our engineers to your factory to install the machines and train your staff how to operate the machines.

Q6: How about the spare parts?

A6: After we deal down all the things, we will offer you a spare parts list for your reference.

Q7: How to join EQS and become an agent?

A7: We sincerely invite you to become our filling machine agent and jointly expand the market. By contacting us, submitting company information for qualification evaluation, and ultimately signing an agency agreement, you will receive comprehensive product training and market support.

Copyright © JIANGSU EQS MACHINERY CO.,LTD