The game of beverage production is transforming, and embracing automation is key. Automated filling lines present a realm of possibilities for small to medium enterprises (SMEs) in the beverage sector.

Automated filling lines enhance operational efficiency, reduce labor costs, and ensure consistent product quality. They enable SMEs to scale operations with precision, meeting increasing demand and sustaining growth.

Tap into the future of beverage production and discover how automation can be a game-changer for your business.

Efficiency is the foundation of staying competitive. Automation promises this efficiency.

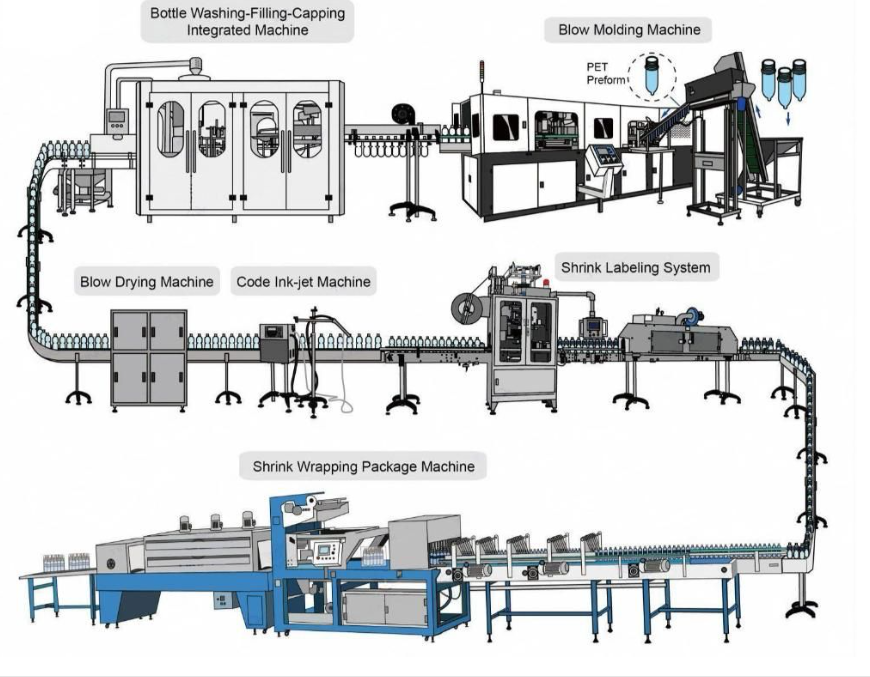

Automated systems streamline the production process, reducing manual intervention and the risk of human error. By handling tasks like filling, capping, and labeling, they ensure a smoother, faster production flow, resulting in higher throughput and reduced downtime.

All these factors contribute to a dependable supply chain and happier customers.

Cost savings are crucial for SMEs to thrive in a competitive market. Automation cuts costs significantly.

Adopting automated filling lines decreases labor costs and minimizes waste from production errors. These savings can be reinvested into other areas of the business, fostering growth and innovation.

Increased financial flexibility allows SMEs to expand and innovate more readily.

Scalability is vital for businesses looking to expand. Automated lines make scalability achievable.

These systems allow SMEs to increase production capacity effortlessly as demand grows. Whether launching new products or entering new markets, automation supports a seamless scale-up without compromising product quality or delivery timelines.

Automation equips SMEs to venture confidently into new market territories.

Looking beyond the immediate benefits, automation sets SMEs on a path for long-term success.

With increasing pressure to innovate, those who embrace automation are well-positioned to adapt to future industry changes. This proactive stance not only boosts competitiveness but also assures business sustainability in an evolving market landscape.

Committing to automation prepares SMEs for both current success and future opportunities.

Automated filling lines empower beverage SMEs with increased efficiency, reduced costs, and scalability, ensuring sustained growth and market adaptability.

My name is Lynn, and I'm an expert in filling machine technology at EQS, a leading liquid packaging solution provider based in China. If you're looking for top-quality equipment for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.

Copyright © JIANGSU EQS MACHINERY CO.,LTD