|

Technical Data

|

|

|

Power supply

|

380V 50Hz 10KW

|

|

Labeling outlet speed

|

Stepless Automatic Transmission

|

|

Labeling accuracy

|

±1mm (related to the shape of labeling object shape and the accuracy of the label)

|

|

Label output accuracy

|

±0.2mm

|

|

Inner diameter of label roll core

|

Φ76.2mm

|

|

Maximum label diameter

|

Φ400mm

|

|

Maximum label height

|

H150mm

|

|

Minimum label height

|

H15mm

|

|

Maximum size of labeling object

|

Diameter≤85mm

|

Boost Your Production. Inquire Today!

Label - Feeding Disk

The independent servo cooperates with the buffer clutch for unwinding to ensure the stability of label - feeding. The label - disk has an air - inflation tensioning structure, and the air - valve switch control is convenient, reducing the label - changing time. The 304SUS support structure is stable and durable.

Correction Device

Through the cooperation of the automatic edge - position controller and the independent servo label - feeding roller, the label - feeding accuracy is ±0.3mm, and the label inclination angle is ≤1° to ensure the stability of label cutting.

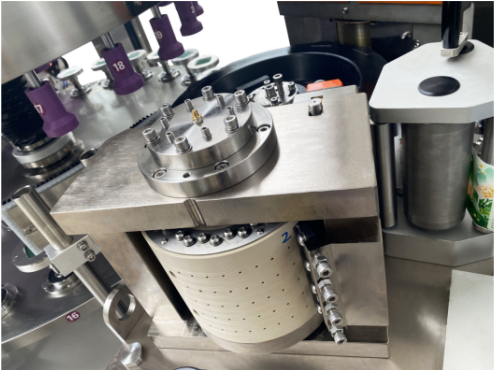

Vacuum Cutter Drum

The cutting knives are made of imported German materials, which are resistant to high temperature and wear - resistant. The self - developed cutter drum adopts a constant - temperature cooling method, preventing the cutting knives from heating up during high - speed operation, prolonging the service life. The non - breakage rate of labels is ≤1%, and the cutting accuracy is about 1mm.

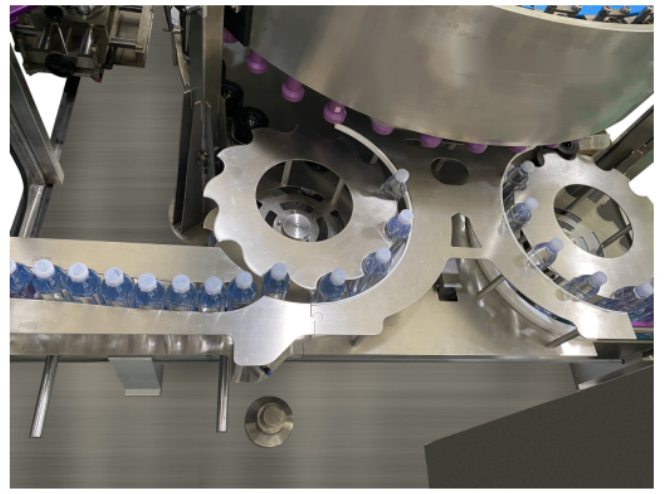

Pressure-Free Bottle Infeed (Compatible with A/B Methods)

A: The star - wheel for bottle - in and bottle - out is customized 1:1 with the product. The contact parts with the product are all polished. The central guide plate is made of stainless steel, which is effective in preventing product scratching. The star - wheel is equipped with an overload device. In case of bottle jams or other external factors, it will automatically alarm and stop. It has a good safety performance. After troubleshooting, reset the star - wheel and start the equipment to resume operation.

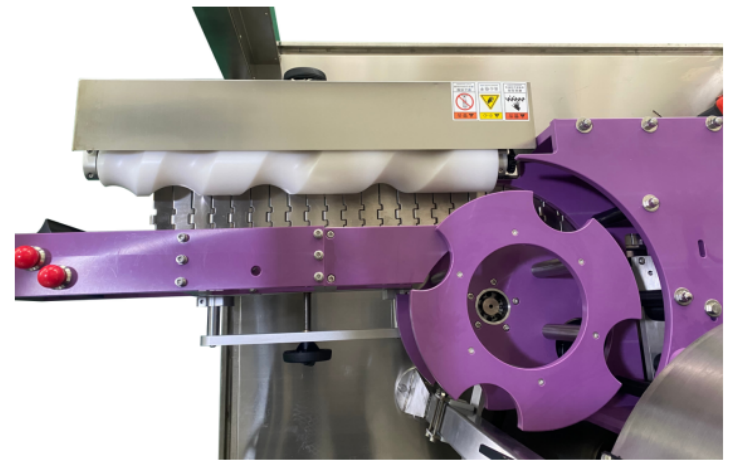

B: The Screw Cooperates with the Star - wheel for Bottle - in

It uses super - high - molecular - weight materials and is customized 1:1 with the product. The star - wheel is equipped with an overload device. In case of bottle jams or other external factors, it will automatically alarm and stop, with good safety performance. After troubleshooting, reset the star - wheel and start the equipment to resume normal operation.It is suitable for conical bottles (with a large angle), oval bottles, square bottles, special - shaped bottles, glass containers, metal containers, etc

Stop - Intercepting Mechanism

Online photoelectric eyes are installed 3M at the front and rear ends of the equipment to detect whether the production - line materials are full. When the front section is blocked or the rear section is empty, the PLC immediately controls the air cylinder to start the stop - intercepting. The equipment can switch from high - speed operation to low - speed operation or standby sleep mode to save energy. When the online photoelectric eye signal is received again, the air - cylinder stop - intercepting is closed, and the equipment switches from low - speed operation to high - speed operation state. The automatic control requires no manual operation.

With over 20 years of industry experience, we have established ourselves as a leading provider of beverage production line solutions worldwide. Our state-of-the-art manufacturing facility spans over 50,000 square meters and is equipped with advanced machinery and technology.

We pride ourselves on our commitment to quality, innovation, and customer satisfaction. Our team of experienced engineers and technicians work closely with clients to understand their specific needs and deliver customized solutions that exceed expectations.

Q1: Are you a trading company or a manufacturer?

A1: We are a manufacturer, we supply the factory price with good quality,our Engineer Team with over 20 year's experience,welcome to visit!

Q2.How can I know your machine has good quality?

A2:We will send the video of testing the machine working condition for you before delivery,so you can send us your bottle samples for a trial.

Q3:What's your guarantee or the warranty of the quality if we buy your machines?

A3: We offer you high quality machines with 15 months guarantee and supply life-long technical support.

Q4: When can I get my machine after I paid?

A4: The delivery time is based on the exact machine you confirmed.

Q5: How can I install my machine when it arrives?

A5: We will send our engineers to your factory to install the machines and train your staff how to operate the machines.

Q6: How about the spare parts?

A6: After we deal down all the things, we will offer you a spare parts list for your reference.

Q7: How to join EQS and become an agent?

A7: We sincerely invite you to become our filling machine agent and jointly expand the market. By contacting us, submitting company information for qualification evaluation, and ultimately signing an agency agreement, you will receive comprehensive product training and market support.

Copyright © JIANGSU EQS MACHINERY CO.,LTD