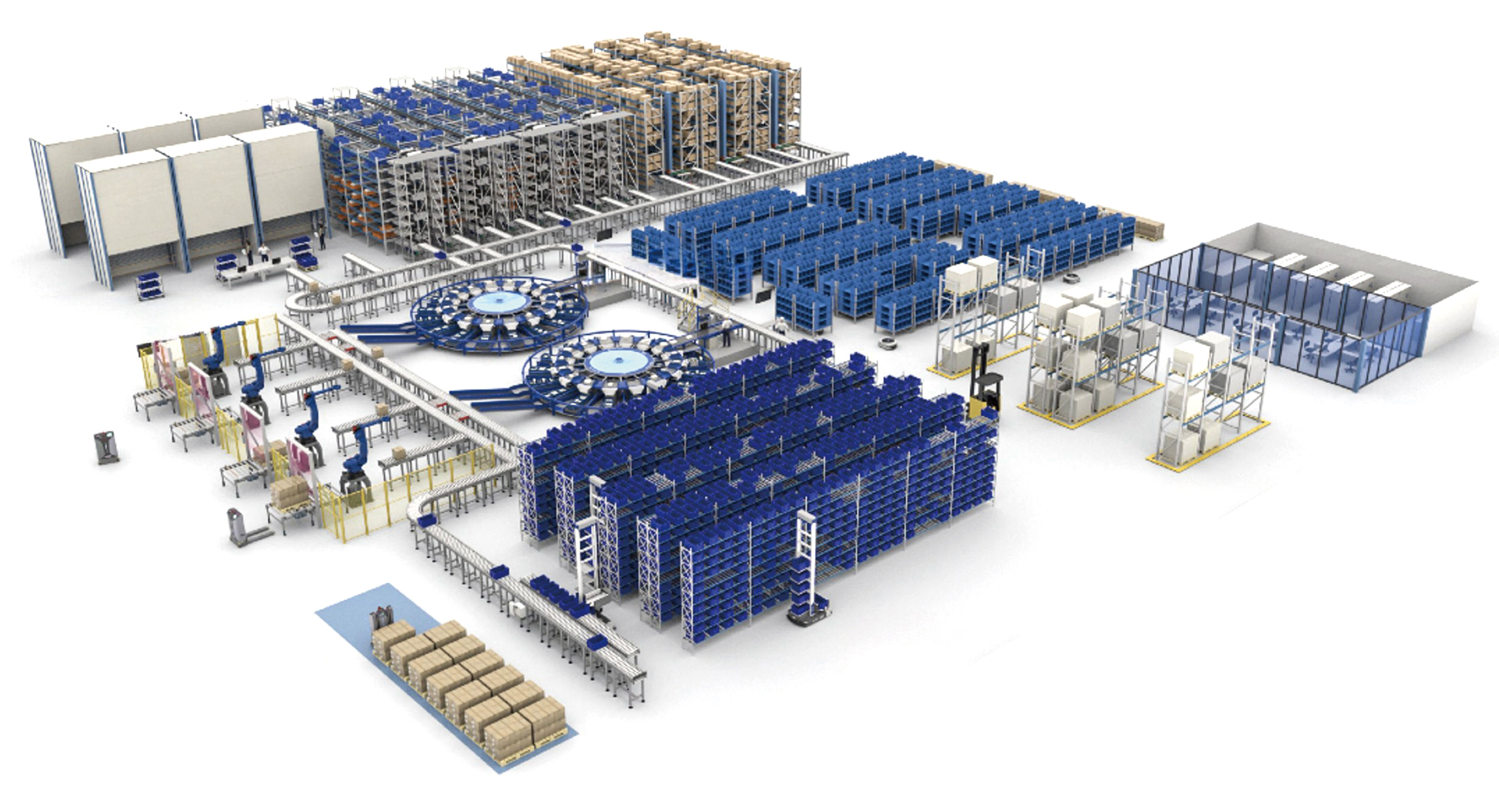

Maximizing warehouse efficiency is crucial for remaining competitive. Automated Storage and Retrieval Systems (AS/RS) promise better organization, quicker access to inventory, and reduced operational costs.

Automated Storage and Retrieval Systems (AS/RS) enhance warehouse efficiency by maximizing space through vertical storage, cutting labor costs, and increasing speed and accuracy, leading to faster order fulfillment and higher throughput.

Adopting AS/RS in your warehouse could transform your operations, but understanding how it works and its benefits is key to making the right decision. Let us break down the key areas of impact.

Warehouse space is a premium cost, and managing it efficiently is vital. By utilizing vertical height, AS/RS systems make the most out of the available footprint.

AS/RS systems maximize warehouse space by storing items vertically, efficiently utilizing available height rather than spread. This allows for increased inventory capacity without expanding floor space.

With AS/RS, the system's software can optimize the placement of items, making sure that commonly accessed products are within easy reach, while less frequently needed items are stored higher up. Here is a simple breakdown:

| Benefit | Description |

|---|---|

| Vertical Storage | Uses less floor space by leveraging height |

| Smart Placement | Prioritizes item placement for efficiency |

| Increased Capacity | More inventory stored per square footage |

This approach not only saves on the cost of renting or owning larger facilities but also accommodates scaling up business operations without physical expansion.

Labor is one of the highest expenses in any warehouse operation. AS/RS technology reduces these costs significantly.

AS/RS systems reduce labor costs by automating repetitive tasks traditionally done by humans, such as item storage and retrieval, thus decreasing dependency on manual labor and associated expenses.

Automated systems replace labor-intensive processes with precise technology. Lower operational costs arise from:

Automation also facilitates 24/7 system operations, maximizing productivity around the clock without additional salaries.

Efficient operations depend on more than just saving space and reducing costs. Speed and accuracy are essential for timely order fulfillment.

AS/RS improves speed and accuracy by automating the retrieval and storage processes, minimizing human error, reducing travel time between items, and efficiently tracking inventory levels.

AS/RS utilizes data to optimize routes and item placements, thus avoiding unnecessary delays in item retrieval. Here's how this impacts operations:

| Benefit | Description |

|---|---|

| Optimized Routes | Reduces item retrieval times |

| Accurate Inventory Levels | Real-time updates improve ordering and stock control |

| Enhanced Order Fulfillment | Faster processing of orders leads to higher customer satisfaction |

With technology ensuring speed and precision, staff can focus efforts on value-added activities such as quality control and customer service, improving overall service delivery.

Automated Storage and Retrieval Systems streamline warehouse operations, ensuring optimal space utilization, decreased labor costs, and improved processing speed and accuracy.

Copyright © JIANGSU EQS MACHINERY CO.,LTD