In the world of beverage production, keeping carbonation intact while filling glass bottles is crucial. Our 20,000 BPH carbonated glass bottle filling machine is designed specifically for this task.

This machine expertly combines speed and precision, ensuring that your beverages retain their fizz while meeting high production demands.

As we dive into the specifics of our 20,000BPH machine, let's explore what makes it the perfect choice for your carbonated beverage operations.

When it comes to carbonated drinks, the filling process is critical.

Our machine's design integrates cutting-edge technology focused on glass bottles, providing a seamless experience in the production line. Here’s what sets it apart:

These features come together to meet the high demands of beverage manufacturers producing carbonated drinks.

Choosing glass bottles offers unique advantages.

Beyond just aesthetics, glass provides several quality benefits. Here are some reasons why manufacturers opt for glass filling:

| Benefit | Explanation |

|---|---|

| Product Integrity | Glass is inert, ensuring no flavor transfer |

| Recyclable | Environmentally friendly and sustainable |

| Aesthetic Appeal | High-end look makes products more attractive |

| Longer Shelf Life | Glass provides an airtight seal, preserving freshness |

Using a glass filling machine not only enhances product presentation but also supports sustainability efforts.

Understanding the filling process can help ensure optimal operation.

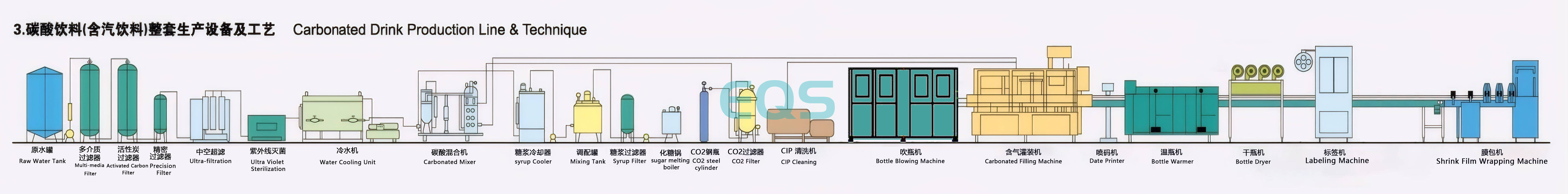

The machine's operation involves several key stages to maintain carbonation and efficiency:

This streamlined process guarantees efficiency and quality throughout production.

Our experience and positive track record stand behind our machines.

With a focus on quality and customer satisfaction, we provide:

Our 20,000BPH carbonated glass bottle filling machine is optimized for high performance and quality. With our commitment to innovative solutions, we can help elevate your beverage production line.

My name is Allen, and I'm an expert in filling machine technology at EQS, a leading liquid packaging solution provider based in China. If you're looking for top-quality equipment for your production line, feel free to reach out to me at [email protected]. We specialize in providing customizable solutions with cutting-edge technology.

Copyright © JIANGSU EQS MACHINERY CO.,LTD