Looking to scale up beverage production without compromising quality? Discover how our 24,000 BPH line can be the solution.

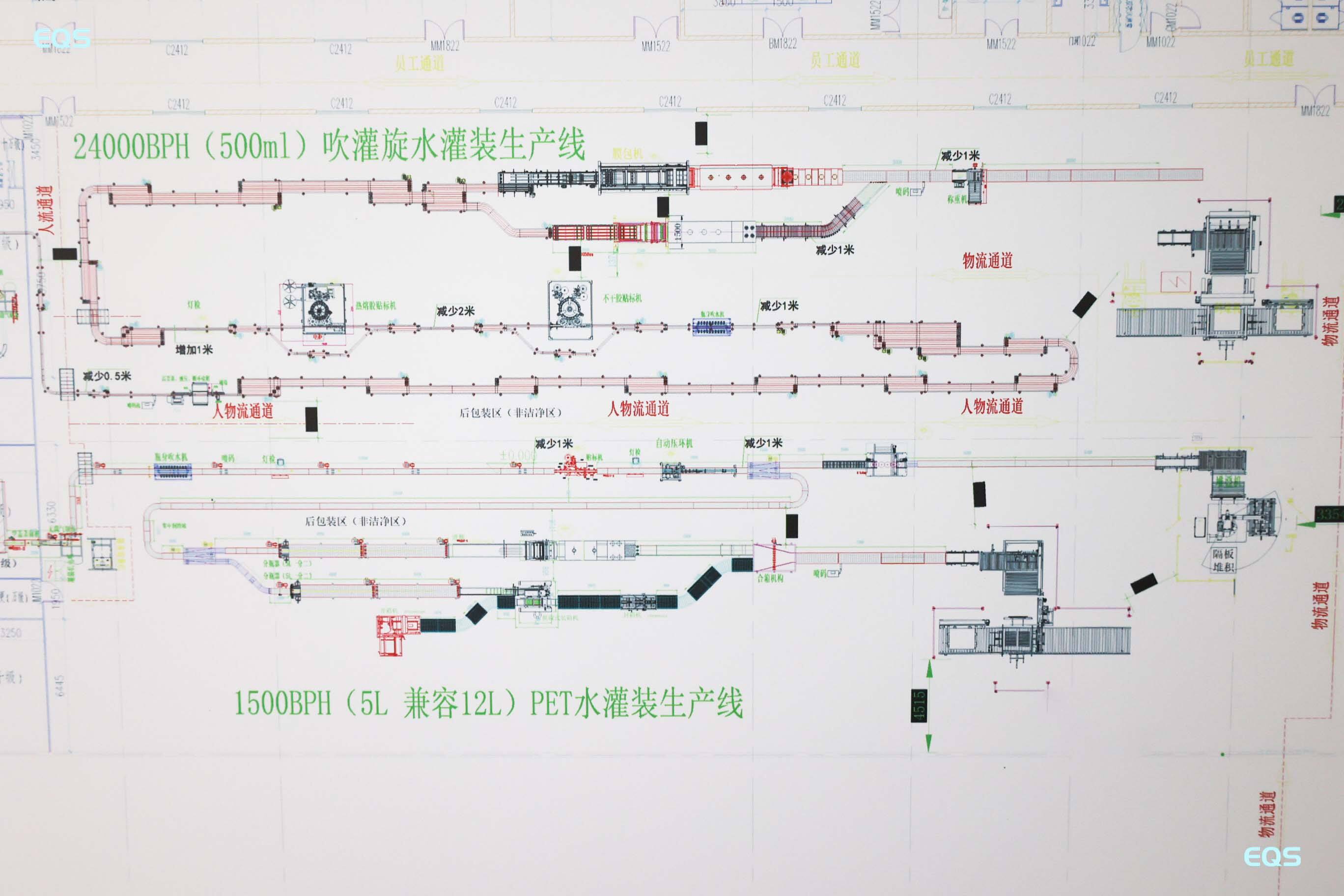

Increasing production capacity while maintaining quality is crucial for growth. Our 24000BPH water blowing, filling, and capping line provides efficiency and consistency, making it an optimal choice for expanding beverage businesses.

Dive into the specifics of how this production line can revolutionize your operations.

Exploring distinct features adds value. Understanding these can influence your choice.

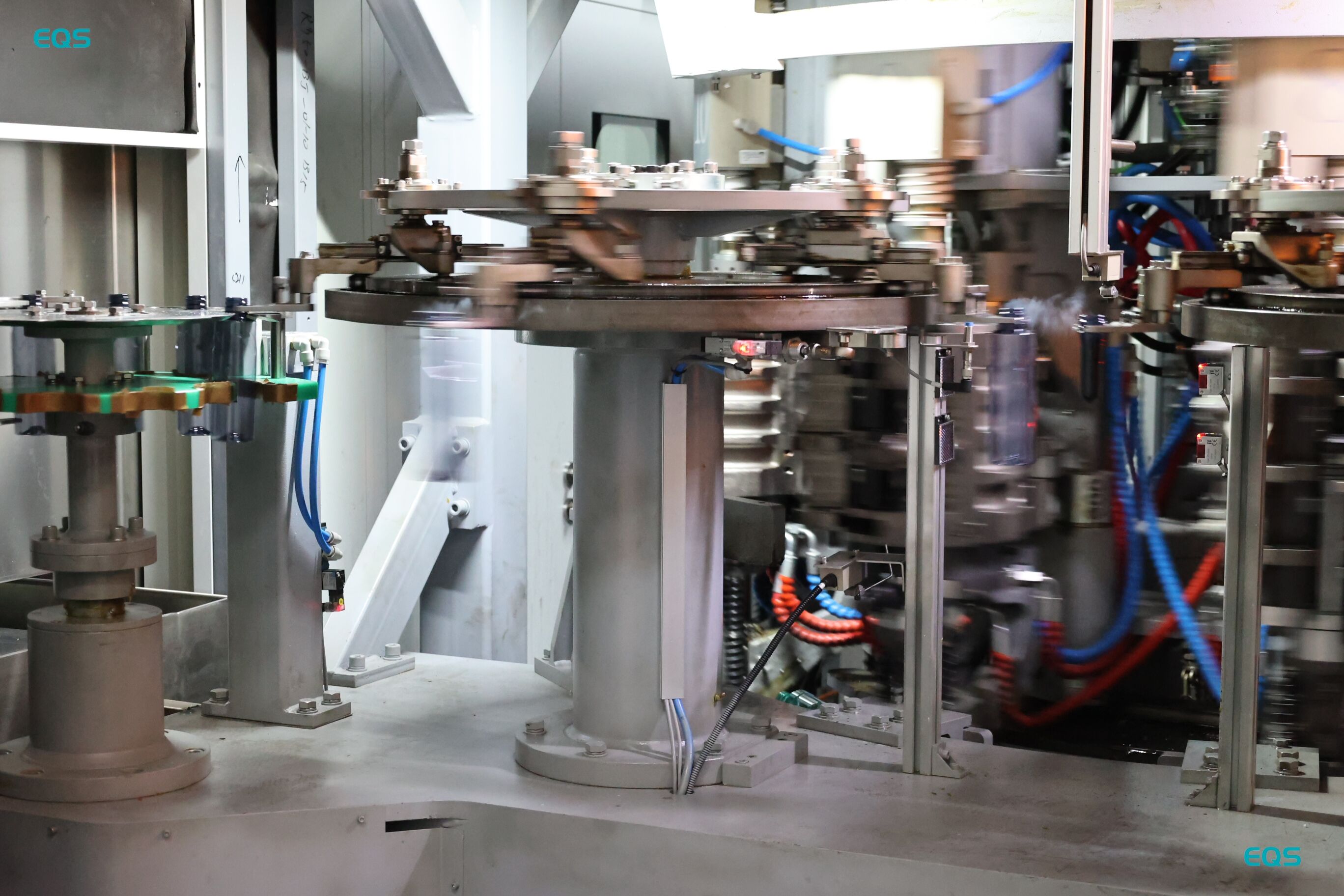

The line integrates a compact design with advanced automation, optimizing space and resources. It ensures high-speed production with minimal downtime, providing a seamless workflow from bottle creation to capping, ensuring each unit maintains quality and integrity.

These attributes keep operations smooth and efficient, enhancing output.

Quality assurance is non-negotiable. Our production line excels in maintaining standards.

Incorporating stringent quality checks throughout the process, the line leverages real-time monitoring for fill accuracy and sealing integrity. Automated sensors and manual checkpoints work together to flag inconsistencies, ensuring consumer satisfaction and product safety.

These systems fortify the production line's reliability and product standard.

Efficiencies streamline business operations. Identifying these enhances decision-making.

The line significantly lowers operational costs through energy efficiency and reduced labor requirements. Its integrated design minimizes resource waste and requires fewer personnel to operate, translating to direct savings and higher profitability.

Operational efficiencies yield greater margins, helping businesses thrive.

Technology integration advances production capabilities. It supports modern manufacturing demands.

Our line incorporates IoT and smart technology for predictive maintenance and real-time production insights. This integration aids in performance optimization and swift issue resolution, aligning the production line with industry advancements for continued competitiveness.

Embracing technology ensures the production line remains competitive and agile.

Our 24000BPH water blowing, filling, and capping line represents a commitment to efficiency, quality, and modern technology integration, providing invaluable advantages in production scaling.

Copyright © JIANGSU EQS MACHINERY CO.,LTD